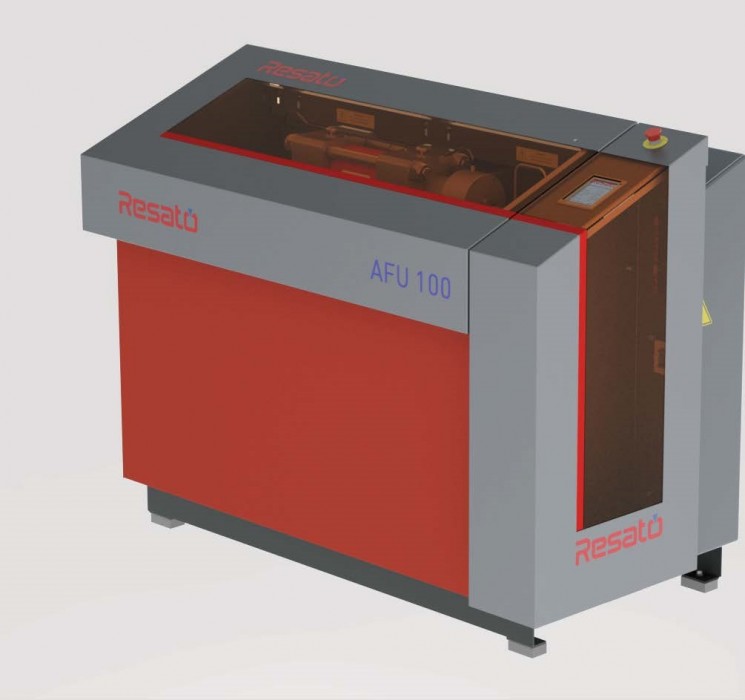

The AFU100 is designed for autofrettage a variety of products

A fully programmable high pressure is applied in order to extend object lifetime. Autofrettage is a process to increase the load bearing capacity of for instance thick walled cylinders by generating stresses, large enough to cause yielding within the inner wall of the cylinder. When the pressure is released, circumferential stress is developed to a certain depth at the bore. These residual stresses serve to reduce the tensile stress which will be generated when the operating pressure will be applied, and will therefore increase the load bearing capacity and increase the fatigue strength.

Key Features

- Fully programmable pressure curve

- Controlled pressure build-up and bleed

- Automatic generated test report

- Data storage

- Touch screen operation

Typical Applications

- Thick walled tubes

- Diesel engine components

- Hydraulic cylinders

- Oil field components

- Water jet components

- High pressure components

Key Specification

- Maximum pressure up to 10.000 bar

- Accuracy of pressure ≥ 0,5% FS

- All high pressure parts made of non-corrosive materials